The Dutch Building Agreement Steel

The escalating demand for environmentally friendly practices creates an urgent imperative for the construction industry to capitalize on this moment, embrace new mindsets and establish standards for transitioning towards a greener future. As a sector encompassing the production of materials for buildings and infrastructure, the construction industry heavily relies on substantial quantities of materials, often of a weighty nature, such as stone, concrete and steel. The extraction, processing and transportation of these materials exert a considerable strain on the environment. The industry accounts for more than 25 % of global CO2 emissions and causes air pollution, the release of toxic substances into water bodies, significant waste and severe impact on the landscape. To maintain a clean and safe living environment for future generations, a fundamental shift towards sustainable construction is imperative. This implies that the construction industry will need to operate within the planetary boundaries, within which humanity can continue to develop, while concurrently pursuing economic prosperity and social equity. The governance of this crucial shift towards sustainable construction has received limited attention so far. How the transition to sustainable construction may be accomplished despite the barriers encountered is discussed below. The focus is on the Dutch Building Agreement Steel, which sets high sustainability ambitions for the entire value chain. Steel is chosen as the illustrative example due to its extensive use in the building sector, significant environmental impacts and its role as a major contributor to carbon emissions, accounting for approximately a quarter of emissions in the building construction process. Given the magnitude of these impacts, there is an urgent need to develop a practical and viable path forward.

1 Barriers to change

The transition towards a sustainable construction industry faces a myriad of challenges and complexities. The construction sector has traditionally been perceived as slow to adopt technological advancements and innovations. This can be attributed to the traditional nature of construction activities and the industrial ecosystem’s fragmentation. The construction process necessitates the involvement of numerous professionals, leading to a complex network of stakeholders. Additionally, construction supply chains are often intricate, relying on inputs and services from various sources, including providers of energy-intensive construction products such as steel, glass, aluminium, mineral products (cement, concrete and concrete products), chemical products (asphalt, paint, varnish) and clay products (bricks and tiles). These materials are frequently sourced through international trade. Furthermore, the construction industry grapples with chronic issues such as project delays (affecting 70% of projects), cost overruns (averaging 14 % of contract costs) and material waste generation (amounting to approximately 10 % of material costs). The transition towards a sustainable construction ecosystem is further impeded by a range of barriers, the most significant of which include:

- a lack of regulatory requirements which would drive demand for circular approaches

- insufficient standards for secondary materials and lack of consensus on end-of-waste status

- challenges in comparing construction products using environmental criteria

- economic feasibility hindered by unfavourable market conditions and a dearth of financial incentives

- limited awareness within the construction industry

The steel construction sector encounters analogous commercial, structural and regulatory barriers. The sector’s typically narrow profit margins constrain the steel producers’ willingness to invest in green technologies. Another obstacle stems from the fact that individual developers do not routinely account for emissions resulting from the steel they utilize. This situation arises due to a combination of factors, including the absence of industry standards, patchy regulation and a lack of tools to measure embodied carbon. The third significant barrier to adoption pertains to the steel industry’s services within a highly fragmented construction landscape. Given this intricate context, effecting substantial change at scale becomes considerably challenging.

THE TRANSITION TOWARDS A SUSTAINABLE CONSTRUCTION INDUSTRY FACES A MYRIAD OF CHALLENGES AND COMPLEXITIES

How to address and overcome these barriers and the governance mechanisms required for achieving sustainable construction has received limited attention. Publications often focus on environmental management systems in the construction industry, identification and assessment of environmental aspects throughout the life cycle of construction products, technical aspects of sustainable construction, indicators of environmental performance, and environmental tools and certifications within the construction industry. But the most important question is how to effectively eliminate these barriers and govern the transition towards sustainable construction.

How to address and overcome these barriers and the governance mechanisms required for achieving sustainable construction has received limited attention

2 The Dutch Building Agreement Steel

Steel is utilized as a structural material in various building components such as walls, roofing, fasteners, building services or substructures. Steel offers inherent advantages such as material efficiency, recycling and reuse, dry construction methods and speed of construction. However, the use of steel in construction also gives rise to significant environmental impacts throughout the product’s life cycle. This includes substantial CO2 emissions during steel production and severe environmental consequences associated with acidification, eutrophication, ozone layer depletion, toxicity and resource depletion. Similarly, design and construction practices often neglect the circularity potential of steel products through intelligent, modular and adaptive design approaches. The challenge lies in effectively harnessing the considerable potential of steel as a sustainable building material.

2.1 Main points of the agreement

In order to reach ambitious sustainability targets, a voluntary partnership of stakeholders representing the entire value chain within the Dutch steel construction sector has been formed. They have recognized the need to formulate and implement a programme that strives for sustainable steel construction. The agreement encompasses diverse interests, connecting organizations throughout the value chain and ensuring collective implementation of the stated ambitions. The fundamental premise of the agreement is to uphold the quality and safety of steel products in construction, including resistance to external influences and other essential requirements.

The execution of the Building Agreement Steel (BAS) has been divided into four distinct phases:

- Preparatory Phase (September 2021–March 2022): preparing and signing the BAS.

- Building Phase (March 2022–December 2023): developing a comprehensive roadmap, appropriate standards, an agreed environmental assessment methodology, a monitoring tool, an innovation programme and procurement requirements.

- Scaling-up Phase (2024–2026): implementing the roadmap through collaboration with commissioning parties, utilizing their procurement procedures.

- Mainstreaming Phase (2026–2030): the BAS becomes the new standard within the industry.

2.2 Results achieved thus far

The Preparatory Phase commenced with the establishment of a coalition of willing stakeholders representing the entire value chain, including commissioning parties. This collaborative effort has resulted in the formation of a core group comprising 24 partners, who officially signed the Building Agreement Steel in March 2022. The signatories have formulated three key sustainability ambitions deemed crucial for delivering substantial sustainability gains within the Netherlands:- Reducing CO2 emissions and applying renewable energy and energy-saving measures throughout the supply chain

- Retaining the value of steel through developing the highest possible level of circularity

- Reducing the environmental impact of substances that pose risks to both human health and the environment

Specific ambitions and target objectives were scheduled for development in the subsequent Building Phase. Notably, the extraction of raw materials from external sources has been recognized as a driver of biodiversity loss, environmental pollution and potential violations of human rights. While the parties involved acknowledge the gravity of these concerns, proactive measures are already being undertaken within the framework of the Dutch International Corporate Social Responsibility agreement for the metal sector and through initiatives such as the Responsible Steel initiative. These activities reflect a commitment to address the social and environmental impacts associated with raw material extraction in the steel industry.

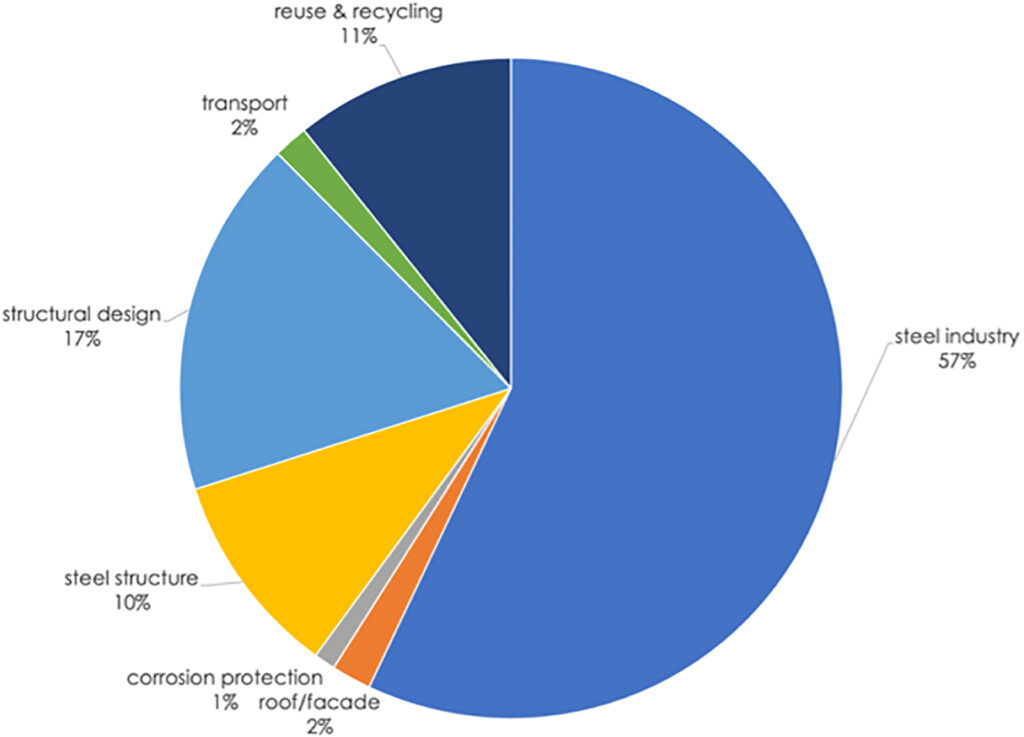

All necessary activities for progressing to the subsequent Scaling-up Phase are prepared during the Building Phase. These encompass the development of a roadmap with specific ambitions and target objectives, as well as the creation of supporting instruments such as standards and an environmental assessment methodology. Additionally, a monitoring tool, an innovation programme and procurement requirements have to be devised. The core group of 24 partners played a pivotal role in supporting the process, convening for working sessions every three months to facilitate the elaboration of these activities. A steering board was also appointed to supervise the implementation. The first task undertaken was to develop a roadmap. Initially, key areas were identified where substantial CO2 improvements can be achieved. This process culminated in an overview of the major focal areas. Figure 1 reveals that significant opportunities for CO2 improvements exist in the steel industry, structural design, steel structures and recycling/reuse.

The overall assessment of the potential CO2 reduction exceeded initial expectations, revealing a significant and attainable reduction of approximately 75–86 %

The core group of partners formed subgroups to explore the key improvement opportunities and assess their potential impact. The first subgroup focused on the steel industry. Notably, major European steel producers have expressed their intention to establish low-CO2 steel mills equipped with advanced furnace technologies powered by either natural gas or hydrogen. Because the BAS does not influence this development, the timeline set by these steel producers for implementing these low-CO2 steel mills was adopted as a given parameter. The circular design subgroup addressed the key options for circularity that can effectively reduce CO2 emissions and minimize the use of primary steel through improved design and construction practices. The reuse and recycling subgroup explored strategies to increase the percentage of steel reuse and promote the utilization of recycled steel. Two other subgroups focussed on steel structures – particularly the use of environmentally friendly high-strength steel – and the use of coatings.

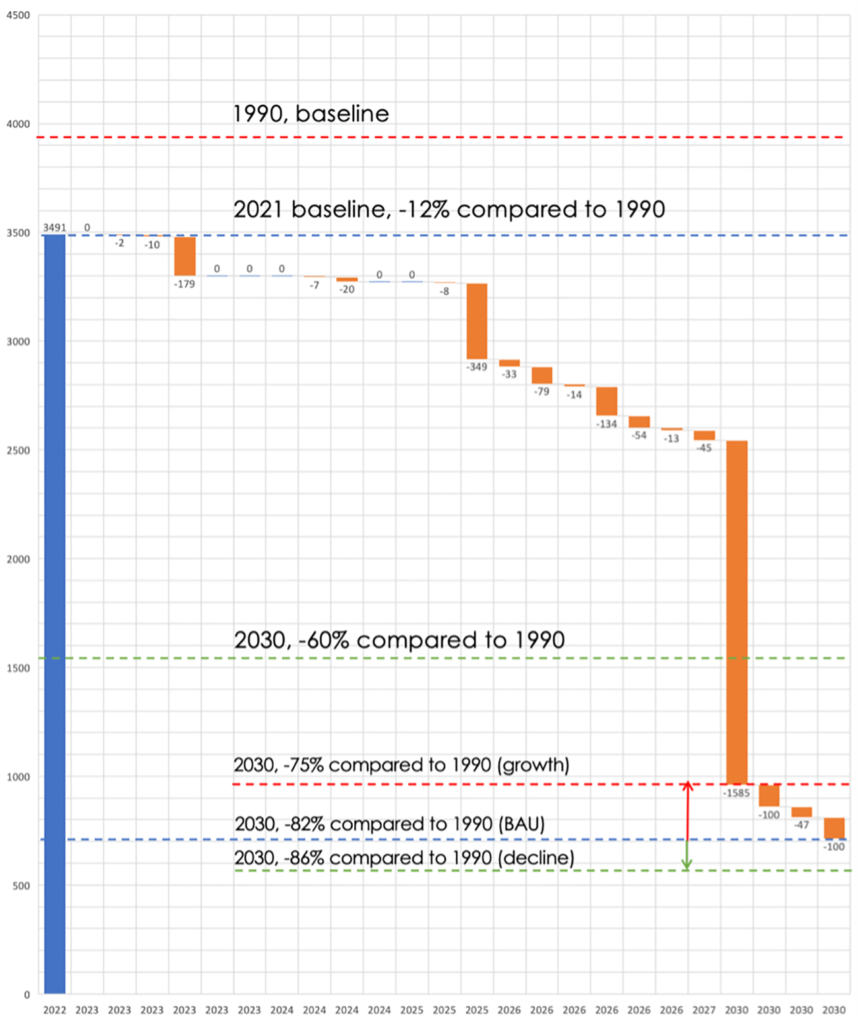

The overall assessment of the potential CO2 reduction exceeded initial expectations, revealing a significant and attainable reduction of approximately 75–86 %, dependent upon the perspective of economic growth. This highlights the significant potential for reducing CO2 emissions within the Dutch steel construction sector. These findings and prioritized options were translated into a roadmap which outlines the necessary environmental improvement steps to be implemented from 2023 to 2030. Importantly, Fig. 2 serves as the basis for formulating progressively stricter procurement terms over time. The active involvement of commissioning parties is vital in this endeavour, as their influence can drive the market towards sustainable practices.

These findings and prioritized options were translated into a roadmap which outlines the necessary environmental improvement steps to be implemented from 2023 to 2030

Addressing the challenge of securing binding commitments from all public and private commissioning parties to align with the ambitions of the BAS has proven to be a significant undertaking. Despite efforts made by the chair of the BAS on behalf of the participants, requests to the national government to enforce these commitments have thus far been unsuccessful. The Dutch government’s main argument revolves around the decentralization of many tasks, including procurement. Consequently, a coalition of willing commissioning parties is currently being mobilized to assume collective leadership in driving change. By uniting their efforts and demanding higher environmental performance from the steel sector, the frontrunners in the market will serve as catalysts for progress. As successful innovations are demonstrated, a wider range of market parties can adopt these innovations as well. It is hoped that this approach will ultimately persuade the government to align procurement requirements across the industry through the implementation of stricter regulations. Given the heavily regulated nature of the construction industry, departing from the current norm of regulations is essential to facilitate the transition towards sustainable construction steel.

With the exception of the challenge of steering the market through the commissioning parties, the majority of activities required for the upcoming Scale-up Phase are nearing completion

With the exception of the challenge of steering the market through the commissioning parties, the majority of activities required for the upcoming Scale-up Phase are nearing completion. A core group of commissioning parties is collaborating on the development of a monitoring tool. Standards for steel quality generally do not impede implementation of sustainable steel, except for a few specific cases that are currently under discussion and appear to be resolvable. Recently, a Dutch Technical Agreement titled Reuse of Construction Steel NTA 8713:2023 was issued, which provides guidelines for the reuse of steel elements. Although a consensus has not yet been reached on a tool to measure the embodied carbon, common ground may soon be found. Furthermore, a significant innovation programme called Green Steel has recently obtained government approval and received a substantial subsidy of 124 million euros. Although the BAS did not play a prominent role in its preparation, it is expected to reap substantial benefits from the ongoing advancements and breakthroughs resulting from this programme. As the activities of the Building Phase draw closer to completion, it is anticipated that the BAS will successfully transition into the Scale-up Phase by the end of 2023.

3 Discussion

The Dutch Building Agreement Steel highlights that achieving a transition to sustainable construction necessitates a systemic change involving the active participation of all relevant actors. No single actor can accomplish this transformation. Ideally, the change process commences with a coalition of willing partners who recognize the imperative of collective action. In the regulated and intricate market of steel construction, the driving force behind change lies with the commissioning parties. A group of frontrunners can accelerate sustainable innovations through their purchasing power. However, to ensure widespread adoption, regulatory reforms are necessary to mainstream these innovations. By harmonizing procurement requirements for the broader peloton of market participants, a level playing field can be established, promoting market fairness and creating certainty regarding the demand for sustainable construction. This, in turn, encourages new entrants to scale up their efforts in line with the sustainability ambitions.

The Dutch case also reveals that the transition process towards sustainable construction follows a sequential progression through four distinct phases: preparatory, building, scaling-up and mainstreaming. It is important to recognize that this process is cyclical, as it necessitates multiple iterations of increasingly comprehensive improvements before reaching the final Mainstreaming Phase, which aims to establish a fully circular system. Governing this transition is akin to embarking on a journey with a clear destination but no pre-defined path. It requires a flexible approach to achieve the set goals effectively. Given the diverse interests and stakeholders operating in separate silos, the appointment of an intermediary, such as the chair of the agreement, becomes crucial. This intermediary, referred to as a transition broker, plays a pivotal role in steering the process, aligning the involved parties and accelerating the transition. By facilitating collaboration and fostering coordination among the various actors, the transition broker helps navigate the complexities and facilitate the progress towards sustainable construction steel.

The governance approach employed in this case study combines elements of public governance and network governance. The national government assumes the role of safeguarding the common good and is responsible for formulating environmental policies, setting policy goals and developing appropriate instruments. However, network governance plays a vital role in accelerating the change process to effectively implement these policies. Network governance involves the collaborative efforts of a network comprising willing parties who exemplify and promote the desired changes. It is important to note that network governance does not replace public governance; rather, it complements it. This approach entails a goal-oriented and formalized framework facilitated by a transition broker. The transition towards more sustainable construction involves a dynamic interplay between various stakeholders, including the value chain itself, commissioning parties, research institutes, and national and local governments.

The governance approach employed in this case study combines elements of public governance and network governance

A comparative study encompassing 16 different countries has shed light on the significant added value of network governance. However, the effectiveness of this approach in supporting public governance is contingent upon the specific socio-cultural and political context. The findings indicate that the network approach, as tested in the Netherlands, has the potential for broader application in various contexts. Consequently, it can be inferred that the construction sector worldwide could make substantial progress towards sustainability by embracing new forms of network cooperation among relevant stakeholders, alongside effective government leadership. By combining these approaches, transformative changes can be realized, fostering sustainable practices and achieving shared ambitions in the construction industry on a global scale.

Jacqueline Cramer, geb. 1951, 1969–1970 Univ. Arkansas; 1970–1976 Biologiestudium Univ. Amsterdam; 1976–1989 Dozentin Univ. Amsterdam; 1987 Promotion in Science Dynamics; 1989–1999 Senior Researcher TNO; 1990–1995 Prof. Umweltschutz Univ. Amsterdam; 1996–2005 Prof. Umweltmanagement Univ. Brabant, Univ. Rotterdam; 2007–2010 Ministerin für Bau, Raumplanung und Umwelt der Niederlande; seit 2006 Prof. Nachhaltigkeitsinnovation Univ. Utrecht; 2010–2015 Direktorin Sustainability Institute; seit 2015 Transformationsbrokerin für komplexe Nachhaltigkeitsthemen

Prof. Dr. Jacqueline Cramer,

Utrecht University, Copernicus Institute

www.uu.nl/en/research/copernicus-institute-of-sustainable-development

References

Cramer, J. (2023) Challenges in implementing sustainable construction – The Dutch Building Agreement Steel as an example. Steel Construction 16, No. 3, pp. 139–143. https://doi.org/10.1002/stco.202300027